Description

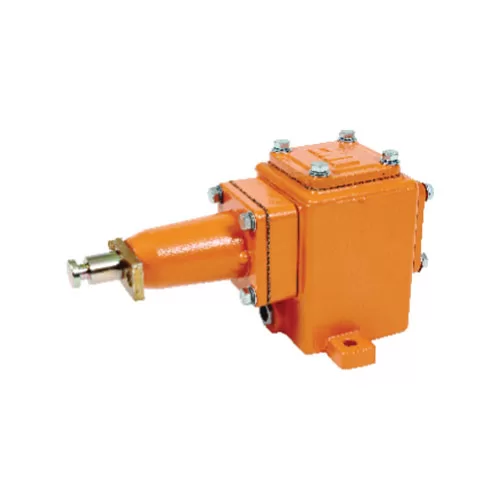

Introducing the Eaton Belt Ripped/Torn Switches – Precision in Power Transmission Protection

Are you seeking unparalleled reliability and efficiency in safeguarding your power transmission systems? Look no further than the cutting-edge Eaton Belt Ripped/Torn Switches. Seamlessly engineered to address the critical issue of belt damage, these switches provide an innovative solution for proactive maintenance, minimizing downtime and maximizing operational continuity.

**Key Features:**

1. **Advanced Sensing Technology:**

The Eaton Belt Ripped/Torn Switches are equipped with state-of-the-art sensing technology, ensuring swift and precise detection of any belt irregularities. This proactive approach allows for instant response, mitigating potential damage and preventing costly disruptions.

2. **Robust Construction:** Crafted with durability in mind, these switches boast a rugged design that withstands the harshest industrial environments. Built to endure heavy-duty applications, the switches ensure longevity and consistent performance, contributing to overall system resilience.

3. **Immediate System Interruption:**

In the event of belt damage, our switches act as an immediate line of defense, interrupting the power transmission system promptly. This instantaneous response not only prevents further damage but also safeguards equipment downstream, enhancing overall system protection.

4. **User-Friendly Installation:** With a focus on user convenience, Eaton has designed these switches for easy installation and integration into existing systems. Their compatibility with various setups ensures a seamless transition, reducing installation time and simplifying the maintenance process.

5. **Comprehensive Monitoring:**

Elevate your predictive maintenance strategy with the comprehensive monitoring capabilities of the Eaton Belt Ripped/Torn Switches. Gain real-time insights into the condition of your belts, allowing for data-driven decision-making and optimizing maintenance schedules.

**Transitioning to Enhanced Reliability:**

In the realm of power transmission protection, Eaton Belt Ripped/Torn Switches represent a paradigm shift. Seamlessly transition from reactive to proactive maintenance, bolstering your system’s reliability and reducing the risk of unplanned downtime. Embrace the future of industrial efficiency with a product designed to exceed expectations.

Invest in the power of foresight – choose Eaton Belt Ripped/Torn Switches for unparalleled reliability, unmatched performance, and a transformative approach to power transmission system protection. Elevate your operations, secure your investments, and experience the epitome of cutting-edge technology in belt monitoring and safeguarding.

Check out our other EATON products https://midmacinternational.com/product-category/electrical/eaton/